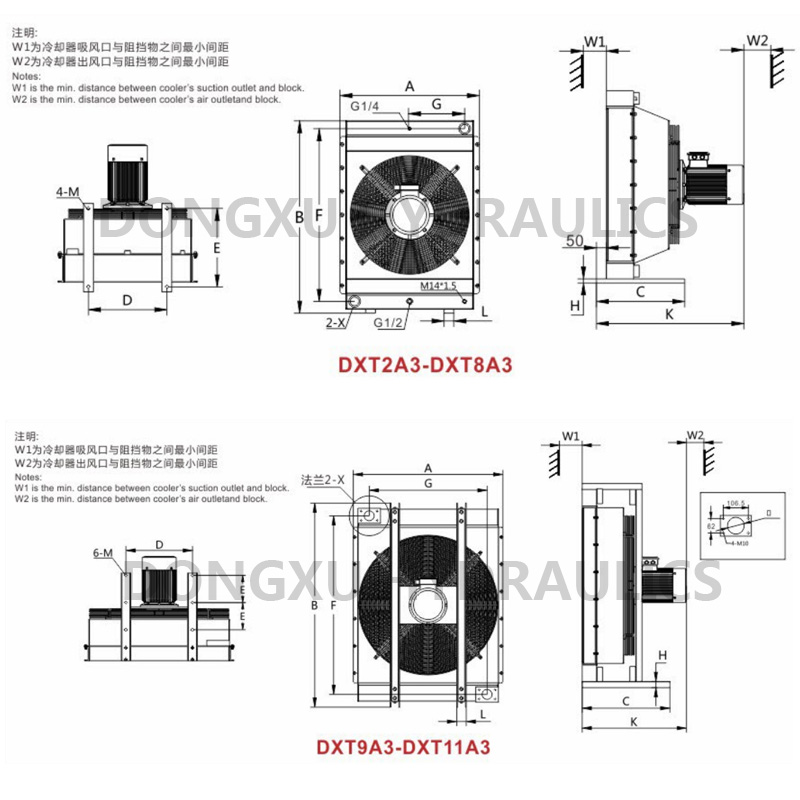

| Model | A | B | C | D | E | G | H | K | L | M | X | F | W1 | W2 |

| DXT-2-A3 | 352 | 415 | 250 | 150 | 200 | 115 | 20 | 470 | 25 | Φ14 | G1" | 345 | 150 | 300 |

| DXT-3-A3 | 456 | 540 | 300 | 200 | 250 | 160 | 20 | 500 | 25 | Φ14 | G1" | 460 | 200 | 400 |

| DXT-4-A3 | 450 | 560 | 300 | 200 | 250 | 160 | 20 | 552 | 30 | Φ14 | G1¼" | 469 | 220 | 450 |

| DXT-5-A3 | 470 | 710 | 300 | 200 | 250 | 165 | 20 | 559 | 30 | Φ14 | G1¼" | 620 | 220 | 450 |

| DXT-6-A3 | 617 | 810 | 400 | 310 | 350 | 235 | 20 | 613 | 50 | Φ16 | G1¼" | 720 | 280 | 550 |

| DXT-7-A3 | 617 | 960 | 400 | 310 | 350 | 235 | 20 | 660 | 50 | Φ16 | G1¼" | 870 | 280 | 550 |

| DXT-8-A3 | 710 | 980 | 450 | 400 | 400 | 280 | 20 | 748 | 50 | Φ16 | G1½" | 880 | 500 | 1000 |

| DXT-9-A3 | 990 | 1350 | 580 | 440 | 215 | 780 | 40 | 730 | 63 | Φ16 | Flange | 1182 | 550 | 1200 |

| DXT-10-A3 | 990 | 1350 | 580 | 440 | 215 | 780 | 40 | 780 | 63 | Φ16 | Flange | 1172 | 620 | 1200 |

| DXT-11-A3 | 1276 | 1570 | 750 | 525 | 210 | 1064 | 48 | 920 | 100 | Φ16 | Flange | 1332 | 800 | 1600 |

Hydraulic machinery

Engineering machinery

Mining machinery

| DXT | 8 | A3 | M | X | O | O |

| Cooler Type: Multi-functional Effective Series | Plate Size: 1/2/3/4/5/6/7/8/9/10/11 | Driving way: A1=DC12V Condensing fan A2=DC24V Condensing fan A3=AC380V A4=AC440V High-efficiency motor A5=Hydraulic Motor | Bypass Valve: M=Without Bypass Valve⬅Standard W=External | Wind Direction: X=Suction⬅Standard C=Blowing | Temp. Controller: O=Without controller⬅Standard T=Temp. Switches--Action Temp.: T50=50℃,T60=60℃,T70=70℃ C=Temp. Transmitter-- C1=Compact,C2=Digital Z=Integrated with a protective temperature control switch. (Only available when the drive mode is a condensing fan) | Heatsink Protection: O=Without protection⬅Standard S=Anti-Stone net |

Construction machinery

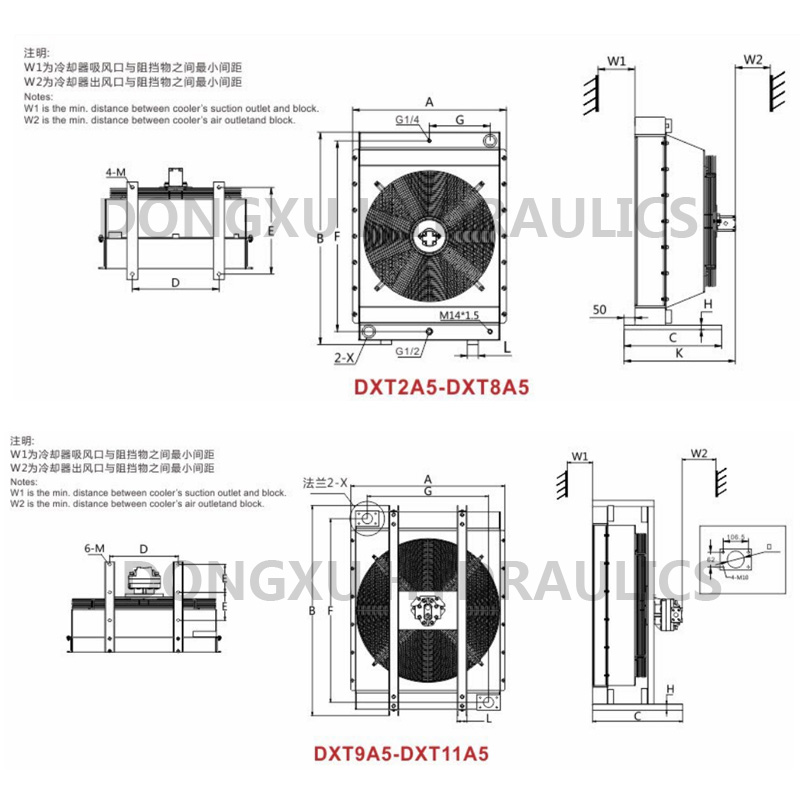

Hydraulic system circuit, independent cooling circuit and lubricating oil cooling system. For examples, machine tools, mining machinery, hydraulic machinery, power station, wind power equipment, and so on.DXT Series Hydraulic Motor Driven Air Coolers| Model | A | B | C | D | E | G | H | L | M | X | F | W1 | W2 |

| DXT-2-A5 | 352 | 415 | 250 | 150 | 200 | 115 | 20 | 25 | Φ14 | G1" | 345 | 150 | 300 |

| DXT-3-A5 | 456 | 540 | 300 | 200 | 250 | 160 | 20 | 25 | Φ14 | G1¼" | 460 | 200 | 400 |

| DXT-4-A5 | 450 | 560 | 300 | 200 | 250 | 160 | 20 | 30 | Φ14 | G1¼" | 469 | 220 | 450 |

| DXT-5-A5 | 470 | 710 | 300 | 200 | 250 | 165 | 20 | 30 | Φ14 | G1¼" | 620 | 220 | 450 |

| DXT-6-A5 | 617 | 810 | 400 | 310 | 350 | 235 | 20 | 50 | Φ16 | G1¼" | 720 | 280 | 550 |

| DXT-7-A5 | 617 | 960 | 400 | 310 | 350 | 235 | 20 | 50 | Φ16 | G1¼" | 870 | 280 | 550 |

| DXT-8-A5 | 710 | 980 | 450 | 400 | 400 | 280 | 20 | 50 | Φ16 | G1½" | 880 | 500 | 1000 |

| DXT-9-A5 | 990 | 1350 | 580 | 440 | 215 | 780 | 40 | 63 | Φ16 | Flange | 1182 | 550 | 1200 |

| DXT-10-A5 | 990 | 1350 | 580 | 440 | 215 | 780 | 40 | 63 | Φ16 | Flange | 1172 | 620 | 1200 |

| DXT-11-A5 | 1276 | 1570 | 750 | 525 | 210 | 1064 | 48 | 100 | Φ16 | Flange | 1332 | 800 | 1600 |

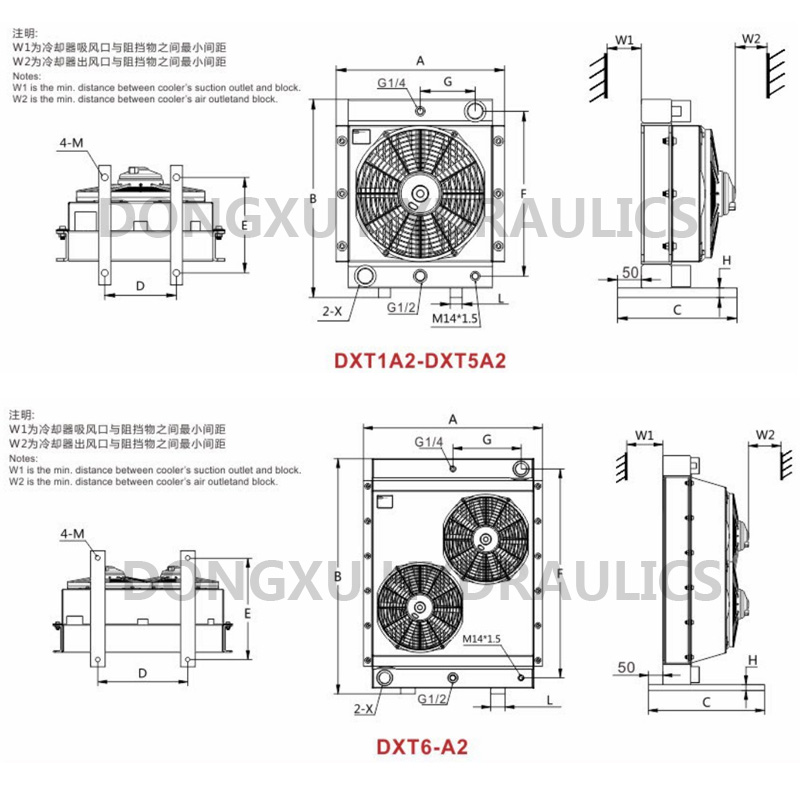

| Model | A | B | C | D | E | G | H | L | M | X | F | W1 | W2 |

| DXT-1-A2 | 270 | 335 | 200 | 80 | 150 | 65 | 15 | 25 | Φ14 | G1" | 270 | 100 | 250 |

| DXT-2-A2 | 352 | 415 | 250 | 150 | 200 | 115 | 20 | 25 | Φ14 | G1" | 345 | 150 | 300 |

| DXT-3-A2 | 456 | 540 | 300 | 200 | 250 | 160 | 20 | 25 | Φ14 | G1" | 460 | 200 | 400 |

| DXT-4-A2 | 450 | 560 | 300 | 200 | 250 | 160 | 20 | 30 | Φ14 | G1¼" | 469 | 220 | 450 |

| DXT-5-A2 | 470 | 710 | 300 | 200 | 250 | 165 | 20 | 30 | Φ14 | G1¼" | 620 | 220 | 450 |

| DXT-6-A2 | 617 | 810 | 400 | 310 | 350 | 235 | 20 | 50 | Φ16 | G1¼" | 720 | 280 | 550 |

| Model | Motor Voltage (V) | Motor Power (KW) | Blade Speed (r/min) | Noise Level (dB) | Cooling Capacity (KW) | Max.Working pressure (bar) | Max.Temp. (℃) | Max.Flow (l/min) |

| DXT-1 | 12 | 0.12 | 2700 | 70 | 5.5 | 20 | 130 | 60 |

| 24 | 0.15 | |||||||

| DXT-2 | 12 | 0.12 | 2700 | 75 | 10 | 20 | 130 | 100 |

| 24 | 0.15 | 73 | ||||||

| 220/380 | 0.25 | 1450 | 78 | |||||

| Hydraulic Motor 10ccm | / | 2800 | 77 | |||||

| DXT-3 | 12 | 0.2 | 2700 | 76 | 16 | 20 | 130 | 150 |

| 24 | 0.2 | 78 | ||||||

| 220/380 | 0.37 | 1450 | 79 | |||||

| Hydraulic Motor 10ccm | / | 2800 | 78 | |||||

| DXT-4 | 12 | 0.2 | 2700 | 77 | 19 | 20 | 130 | 200 |

| 24 | 0.2 | 78 | ||||||

| 220/380 | 0.37 | 1450 | 79 | |||||

| Hydraulic Motor 10ccm | / | 2800 | ||||||

| DXT-5 | 12 | 0.2 | 2700 | 79 | 28 | 20 | 130 | 250 |

| 24 | 0.2 | |||||||

| 220/380 | 0.75 | 1450 | 82 | |||||

| Hydraulic Motor 10ccm | / | 1500 | 80 | |||||

| DXT-6 | 220/380 | 1.5 | 1450 | 87 | 35 | 20 | 130 | 300 |

| Hydraulic Motor 16ccm | / | 1500 | 84 | |||||

| DXT-7 | 220/380 | 1.5 | 1450 | 87 | 55 | 20 | 130 | 350 |

| Hydraulic Motor 16ccm | / | 1500 | 84 | |||||

| DXT-8 | 220/381 | 2.2 | 1450 | 89 | 70 | 20 | 130 | 400 |

| Hydraulic Motor 16ccm | / | 1500 | 85 | |||||

| DXT-9 | 220/381 | 4 | 1450 | 96 | 110 | 20 | 130 | 450 |

| Hydraulic Motor 25ccm | / | 1500 | 87 | |||||

| DXT-10 | 220/382 | 7.5 | 1450 | 102 | 140 | 20 | 130 | 500 |

| Hydraulic Motor 25ccm | / | 1500 | 92 | |||||

| DXT-11 | 220/382 | 11 | 1450 | 106 | 245 | 20 | 130 | 600 |

| Hydraulic Motor 32ccm | / | 1500 | 97 |

Walking machinery

1. The diameter of the piping should be matched with the size of the oil inlet and outlet. It can be smaller at the same time, but cannot be larger at the same time. Use high-pressure hoses and direct heads as much as possible to reduce oil return resistance. 2. When using the oil return cooling method, a bypass unloading circuit must be installed, and the opening pressure of the back pressure valve is less than 0.5MPa to prevent the radiator from being damaged by excessive pulse pressure when the system is started. 3. The location of the air cooler should avoid vibration and punching, and the air intake and exhaust should be free and unobstructed, and the installation should be firm. 4. It is not recommended to install a filter at the oil outlet.